Partner Article

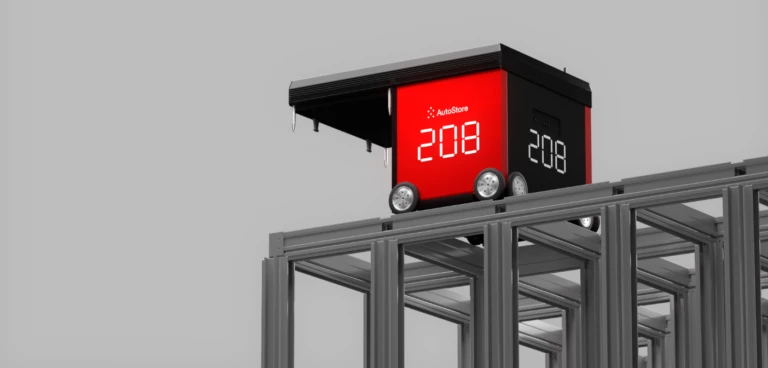

AutoStore Unveils R5+ Robot, Expanding its Bin-Handling Capabilities to Meet the Needs of Rapidly Evolving Warehouses

The new robot, built based on the proven technology of the R5 model, can handle bins up to 425mm

Nottingham based leading warehouse automation company, AutoStore, announces the arrival of its R5+ Robot. The newest addition to the AutoStore Robot fleet will enable warehouses to manage larger items, thanks to the R5+’s ability to handle Bins up to 425 mm, the tallest Bins available in the AutoStore system. Until now, this has been a premium feature possible only with AutoStore B1 Robot installations. The R5+ is now available for operations globally.

The R5+ will give customers the same confidence and first-class performance that has been proven by the R5 for over a decade – with a significant addition. AutoStore has now introduced a more economically competitive offer to companies operating in a wider variety of markets, such as footwear, semiconductors, and other similar applications. The maximum Grid height for AutoStore customers utilizing the R5+ with 425 mm Bins will be slightly higher than a Grid with the R5 using 330 mm Bins, creating a Grid composed of 14 layers of Bins that is around 6,044 mm tall.

“Sometimes the simplest solutions make the biggest transformation,” said Carlos Fernández, Chief Product Officer at AutoStore. “We continue to innovate to help retailers improve the customer experience they offer. If there is one thing we’ve witnessed over the past two years, it is that the retail landscape, particularly in regard to ecommerce, has evolved to demand precision and speed. We’re committed to supporting our customers in becoming even more competitive in high throughput applications.”

The R5+ will continue to provide the fast and reliable service that the AutoStore system is known for, allowing customers to benefit from a solution that is capable of continuous operation.

This was posted in Bdaily's Members' News section by Nicholas Newman .

Restoring confidence for the economic road ahead

Restoring confidence for the economic road ahead

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector

Why investors are still backing the North East

Why investors are still backing the North East

Time to stop risking Britain’s family businesses

Time to stop risking Britain’s family businesses

A year of growth, collaboration and impact

A year of growth, collaboration and impact

2000 reasons for North East business positivity

2000 reasons for North East business positivity

How to make your growth strategy deliver in 2026

How to make your growth strategy deliver in 2026

Powering a new wave of regional screen indies

Powering a new wave of regional screen indies

A new year and a new outlook for property scene

A new year and a new outlook for property scene

Zero per cent - but maximum brand exposure

Zero per cent - but maximum brand exposure