£50m in savings predicted for SMEs that have collaborated with Newcastle Business School

Research undertaken within Northumbria University’s Newcastle Business School has predicted the potential for £50m in savings, as an eight-year projection, for SMEs with which it has collaborated.

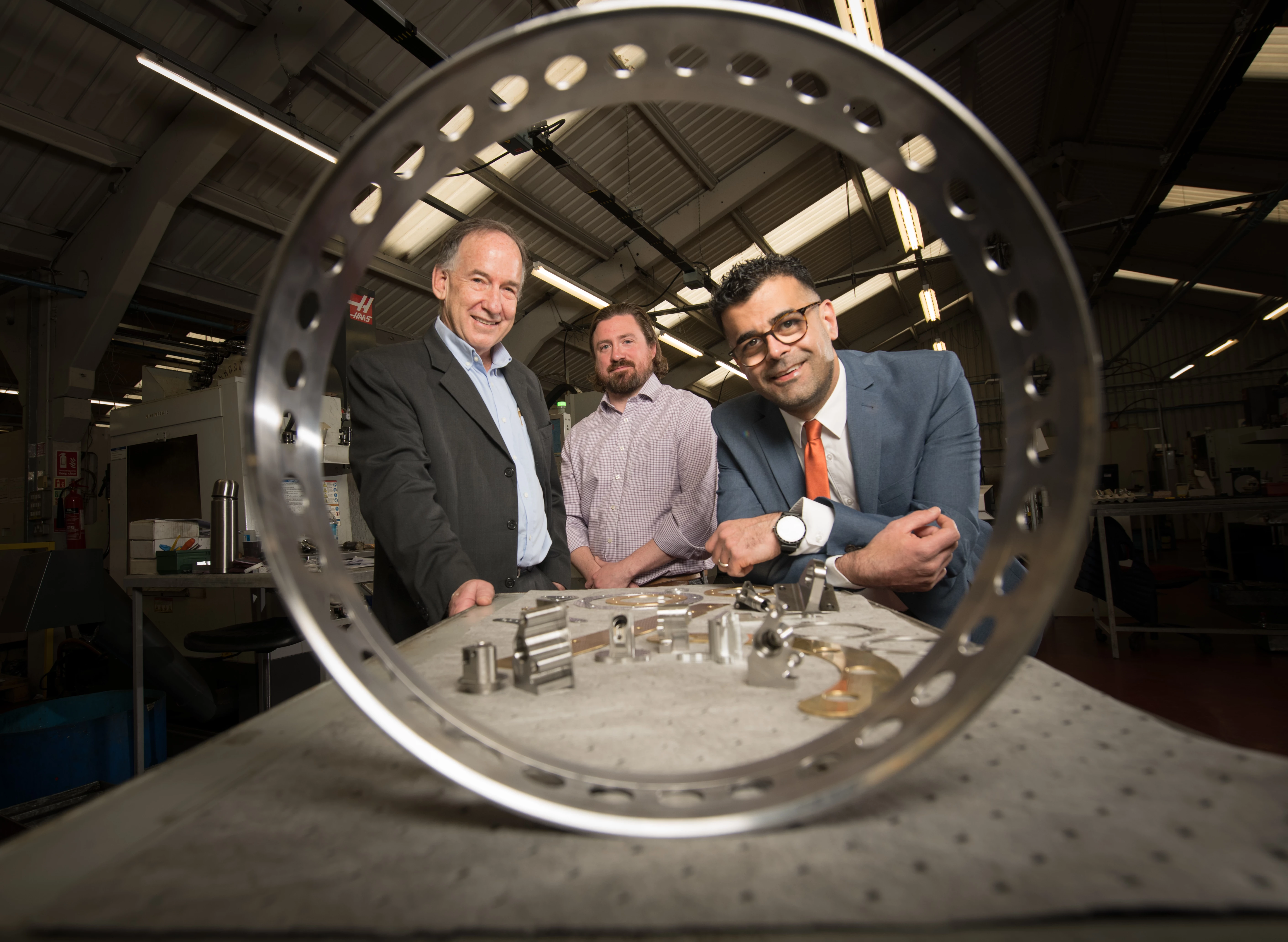

The Research Interest Group, operating within the department of marketing, operations and systems, led by Dr Alireza Shokri, is now keen to broaden its impact with SMEs by reaching out to those operating within supply chains, to help them achieve cost-savings by providing the knowledge to address sustainability and increase business productivity and efficiency.

The group is a frontline platform which shares knowledge and skill with service and manufacturing enterprises of various sizes across the UK and beyond. It works with bodies such as Advanced Manufacturing Forum, Chartered Institute of Purchasing and Supply and Chartered Institute of Logistics and Transport and Chartered Quality Institute.

By way of example of the impact it can have on SMEs, in 2021, the group formed a strategic partnership with NBT Group, a North East based supply chain solution company and Senseye Ltd, a digital predictive maintenance facilitator for global companies in a variety of sectors, to undertake a feasibility study.

The aim of the project was to gain in-depth understanding of the potential for optimising predictive maintenance and supply chain processes and to lay the groundwork for development of an integrated system.

Dr Alireza, associate professor in operations and supply chain management and head of subject group, said: “The message we want to be received by SMEs within the UK market, is those that feel ready to embrace change and innovation in their operations and supply chains, but don’t know where to start, should reach out to our team for help.

“Our partnership with NBT and Senseye addressed one of the Grand Challenges in the UK Industrial Strategy, the artificial intelligence and data-driven economy with particular emphasis on maximising supply chain efficiency to optimise processes and drive efficiencies and productivity increases.

“The feasibility study was incredibly illuminating and our knowledge of how technology can have massive impact, is one of many areas of knowledge we are seeking to exchange with SMEs looking to increase business productivity and efficiency. Brexit and Covid-19 further highlighted the cracks that exist within supply chains and the urgent need to address any weakness.

“Our in-depth research in to supply chains and operations management and how continuous improvement or incremental improvement through knowledge and innovation can streamline operations and processes, has allowed us to predict the potential for £50m in savings, over an eight-year projection, for those SMEs we have looked at and we now want to assist many others.”

Looking to promote your product/service to SME businesses in your region? Find out how Bdaily can help →

Enjoy the read? Get Bdaily delivered.

Sign up to receive our daily bulletin, sent to your inbox, for free.

Restoring confidence for the economic road ahead

Restoring confidence for the economic road ahead

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector

Why investors are still backing the North East

Why investors are still backing the North East

Time to stop risking Britain’s family businesses

Time to stop risking Britain’s family businesses

A year of growth, collaboration and impact

A year of growth, collaboration and impact

2000 reasons for North East business positivity

2000 reasons for North East business positivity

How to make your growth strategy deliver in 2026

How to make your growth strategy deliver in 2026

Powering a new wave of regional screen indies

Powering a new wave of regional screen indies

A new year and a new outlook for property scene

A new year and a new outlook for property scene

Zero per cent - but maximum brand exposure

Zero per cent - but maximum brand exposure