University of Sheffield brings life-saving ‘Robo Doctor’ technology closer to market

New robotic technology that can remotely treat casualties of a terrorist attack or major incident has taken a step closer to entering full production after it impressed at a special Ministry of Defence (MoD) event.

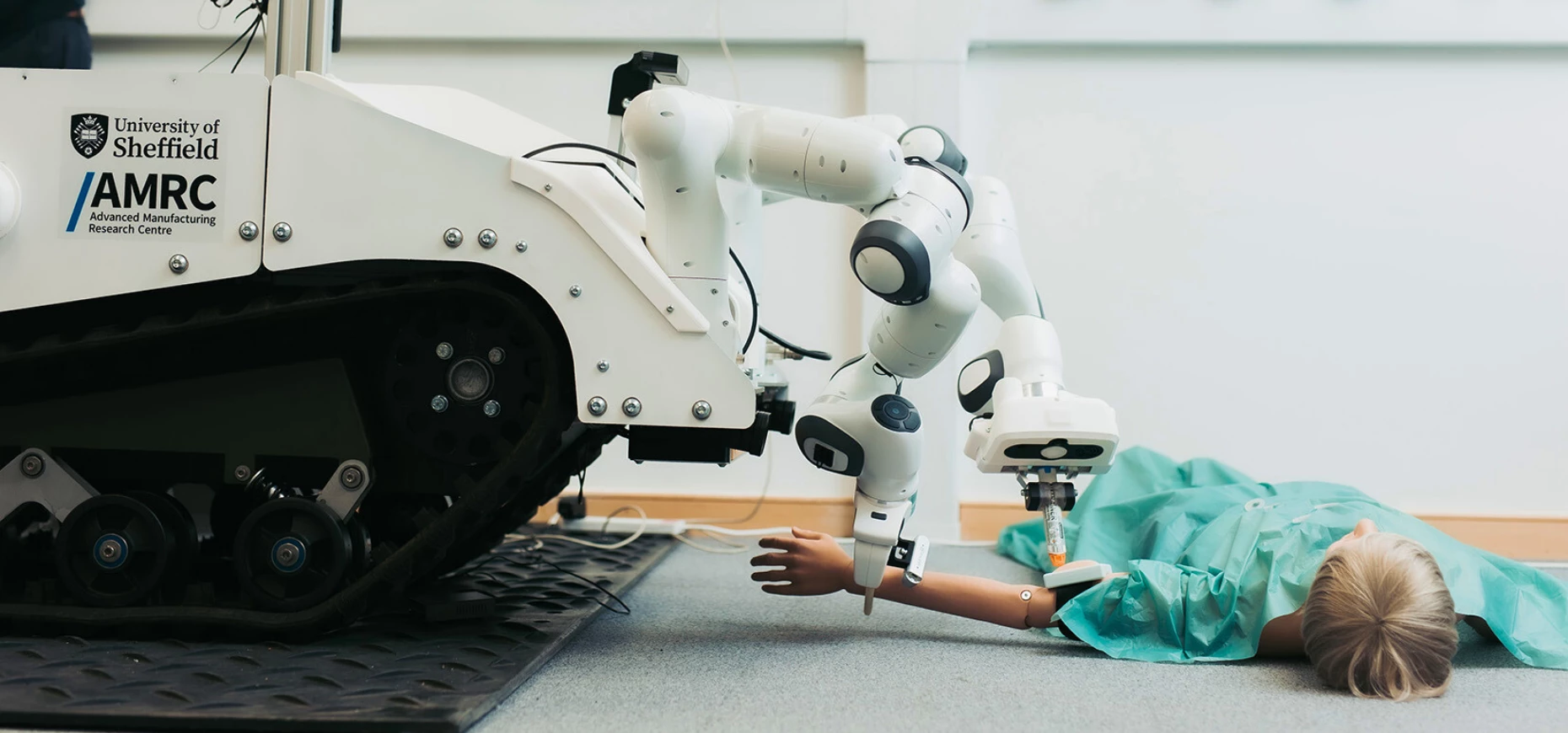

Researchers from the University of Sheffield Advanced Manufacturing Research Centre (AMRC), Sheffield Robotics and Department of Automatic Control and Systems Engineering, successfully put its ‘MediTel’ uncrewed ground vehicle (UGV) through its paces at BattleLab, an initial testing ground for new technologies that can be deployed in hazardous locations.

Design engineers took just nine months to come up with a fully working prototype, leveraging the power of PTC’s Creo 3D Computer Aided Design (CAD) solution to take a standard UGV platform and two robotic arms to create, what many are calling, the next generation ‘Robo Doctor’.

One of three novel telexistence technologies funded through a two-phase £2.3m innovation competition run by the Defence Security Accelerator (DASA), it can be remotely operated from over one mile away by using Virtual Reality (VR).

Rigorous testing has seen it successfully perform a critical initial assessment of a dummy casualty, including taking temperature, blood pressure, heart rate checks and even administering pain relief through an auto-injector.

With the positive feedback emanating from its appearance at BattleLab, it is hoped that additional funding can be found to take the prototype forward with the longer-term possibility of scaling up for manufacturing in the UK.

David King, Head of Digital Design at the AMRC, commented: “Experts from the MoD were amazed that we have come up with a working prototype in just nine months and within the financial budget that was set.

“That is in no small part because of the long-standing relationship we have with digital transformation specialist PTC and its industry-leading design software.

“We went straight from sketches on paper to quickly designing the first model on Creo, utilising all its simulation and custom features to get there within a matter of weeks. This included how we mounted the robot on the platform, the mechanical engineering and how we integrated the power systems and arms.

“There wasn’t lots of time to build practical models, so we had to complete numerous design iterations to get to where we wanted to be and with an operational ‘MediTel’ that could be tested on High Bradfield in the Peak District.”

By Matthew Neville – Senior Correspondent, Bdaily

- Add me on LinkedIn and Twitter to keep up to date

- And follow Bdaily on Facebook, Twitter and LinkedIn

- Submit press releases to editor@bdaily.co.uk for consideration.

Looking to promote your product/service to SME businesses in your region? Find out how Bdaily can help →

Enjoy the read? Get Bdaily delivered.

Sign up to receive our popular Yorkshire & The Humber morning email for free.

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector

Why investors are still backing the North East

Why investors are still backing the North East

Time to stop risking Britain’s family businesses

Time to stop risking Britain’s family businesses

A year of growth, collaboration and impact

A year of growth, collaboration and impact

2000 reasons for North East business positivity

2000 reasons for North East business positivity

How to make your growth strategy deliver in 2026

How to make your growth strategy deliver in 2026

Powering a new wave of regional screen indies

Powering a new wave of regional screen indies

A new year and a new outlook for property scene

A new year and a new outlook for property scene

Zero per cent - but maximum brand exposure

Zero per cent - but maximum brand exposure

We don’t talk about money stress enough

We don’t talk about money stress enough